Grass Assassin Cutter Series

Product Features:

Triangular 5/8 Steel Vented Blade Carrier

BUSHHOG STYLE CUTING BLADES

Bent AXIS Motor

One piece top deck design for strength and structural durability

High Lift Flange Blade for Refined Material

SIDE DISCHARGE SHOOT- refines material

PACK OUT TOOL BOX OR COOLER MOUNT

Standard Motor Cover & Spindle Guard

Fully welded bolt protector on blade carrier

Available jumper hose lengths: 8 ft, and 10 ft

Case Drain Required to Run

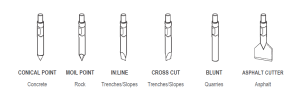

Hydraulic Breakers – Backhoes

Construction Attachments Hydraulic Breaker for Tractor Loader Backhoes are designed for construction and demolition of concrete structures, rocks, asphalt, and more.

Designed for aiding in construction and demolition of concrete structures, rocks, asphalt,?etc.

- Constructed of high-strength steel to provide structural durability

- Silence kit ensures noise protection and prevents dust and debris from entering breaker housing

- Cushion Damper provides protection to the host machine

- Auto Stop (Anti-Blanking Fire) System ensures less problem of the components and longer life of the breaker

- Specify make and model of host machine when placing order

- Weights may vary based on selected hitch styles

- Use of unsuitable hydraulic couplers or hoses can cause damage to internal components of the breaker.

- Dry-firing hydraulic breaker can result in damage to internal components of breaker and host machine.

- Chisel paste must be used with hydraulic breakers; using high-temperature grease as a substitution for chisel paste will cause damage to components of the breaker.

- Consult with appropriately trained hydraulic specialists prior to placing the breaker into service.

- Read the operator's manual before use.

- Check hydraulic flow and pressure before use.

- Instruct the owner/operator on proper use of the hydraulic breaker before delivery of the machine or product.

Hydraulic Breakers – Compact Excavators

Construction Attachments Hydraulic Breaker for Compact Excavators are designed for construction and demolition of concrete structures, rocks, asphalt, and more.

Designed for aiding in construction and demolition of concrete structures, rocks, asphalt,?etc.

- Constructed of high strength steel to provide structural durability

- Silence kit ensures noise protection, prevents dust and debris from entering breaker housing

- Cushion Damper provides protection to the host machine

- Auto Stop (Anti Blank Fire) System ensures less problem of the?components and longer life of the breaker

- Specify make and model of host machine when placing order

- Weights may vary based on selected hitch styles

- Use of unsuitable hydraulic couplers or hoses can cause damage to internal components of breaker.

- Dry firing hydraulic breaker can result in damage to internal components of breaker?and host machine.

- Chisel paste must be used with hydraulic breakers, using high temperature grease as a?substitution for chisel paste will cause damage to components of breaker.

- Consult with appropriately trained hydraulic specialists prior to placing breaker into service.

- Read operators manual before use.

- Check hydraulic flow and pressure before use.

- Instruct owner/operator on proper use of hydraulic breaker before delivery of machine or product.

Hydraulic Breakers – Mid & Large Excavators

Construction Attachments Hydraulic Breaker for Mid-Large Excavators are designed for construction and demolition of concrete structures, rocks, asphalt, and more.

Designed for aiding in construction and demolition of concrete structures, rocks, asphalt, etc.

- Constructed of high strength steel to provide structural durability

- Silence kit ensures noise protection, prevents dust and debris from entering breaker housing

- Cushion Damper provides protection to the host machine

- Auto Stop (Anti Blank Fire) System ensures less problem of the components and longer life of the breaker

- Specify make and model of host machine when placing order

- Weights may vary based on selected hitch styles

- Use of unsuitable hydraulic couplers or hoses can cause damage to internal components of breaker.

- Hydraulic lines < 60 gpm – use 1.0 inch lines AND > 60 gpm – use 1.25 inch lines.

- Dry firing hydraulic breaker can result in damage to internal components of breaker and host machine.

- Chisel paste must be used with hydraulic breakers, using high temperature grease as a substitution for chisel paste will cause damage to components of breaker.

- Consult with appropriately trained hydraulic specialists prior to placing breaker into service.

- Read operators manual before use.

- Check hydraulic flow and pressure before use.

- Instruct owner/operator on proper use of hydraulic breaker before delivery of machine or product.

Hydraulic Breakers – Mini Skid Steers

Construction Attachments Hydraulic Breaker for Skid Steer Loaders are designed for construction and demolition of concrete structures, rocks, asphalt, and more.

Designed for aiding in construction and demolition of concrete structures, rocks, asphalt,?etc.

?

?

- Constructed of high strength steel to provide structural durability

- Silence kit ensures noise protection, prevents dust and debris from entering breaker housing

- Cushion Damper provides protection to the host machine

- Auto Stop (Anti Blank Fire) System ensures less problem of the?components and longer life of the breaker

- Specify make and model of host machine when placing order

- Weights may vary based on selected hitch styles

?

?

- Use of unsuitable hydraulic couplers or hoses can cause damage to internal components of breaker.

- Hydraulic lines < 60 gpm ? use 1.0 inch lines AND > 60 gpm ? use 1.25 inch lines.

- Dry firing hydraulic breaker can result in damage to internal components of breaker?and host machine.

- Chisel paste must be used with hydraulic breakers, using high temperature grease as a?substitution for chisel paste will cause damage to components of breaker.

- Consult with appropriately trained hydraulic specialists prior to placing breaker into service.

- Read operators manual before use.

- Check hydraulic flow and pressure before use.

- Instruct owner/operator on proper use of hydraulic breaker before delivery of machine or product.

Hydraulic Breakers – Skid Steers

onstruction Attachments Hydraulic Breaker for Skid Steer Loaders are designed for construction and demolition of concrete structures, rocks, asphalt, and more.

Designed for aiding in construction and demolition of concrete structures, rocks, asphalt, etc.

- Constructed of high strength steel to provide structural durability

- Silence kit ensures noise protection, prevents dust and debris from entering breaker housing

- Cushion Damper provides protection to the host machine

- Auto Stop (Anti Blank Fire) System ensures less problem of the components and longer life of the breaker

- Specify make and model of host machine when placing order

- Weights may vary based on selected hitch styles

- Use of unsuitable hydraulic couplers or hoses can cause damage to internal components of breaker.

- Hydraulic lines < 60 gpm – use 1.0 inch lines AND > 60 gpm – use 1.25 inch lines.

- Dry firing hydraulic breaker can result in damage to internal components of breaker and host machine.

- Chisel paste must be used with hydraulic breakers, using high temperature grease as a substitution for chisel paste will cause damage to components of breaker.

- Consult with appropriately trained hydraulic specialists prior to placing breaker into service.

- Read operators manual before use.

- Check hydraulic flow and pressure before use.

- Instruct owner/operator on proper use of hydraulic breaker before delivery of machine or product.

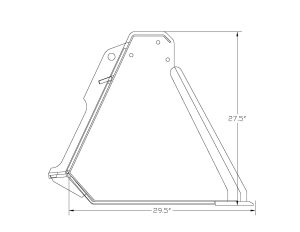

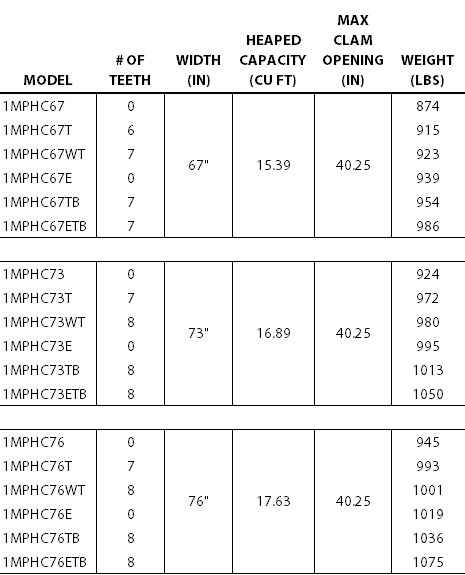

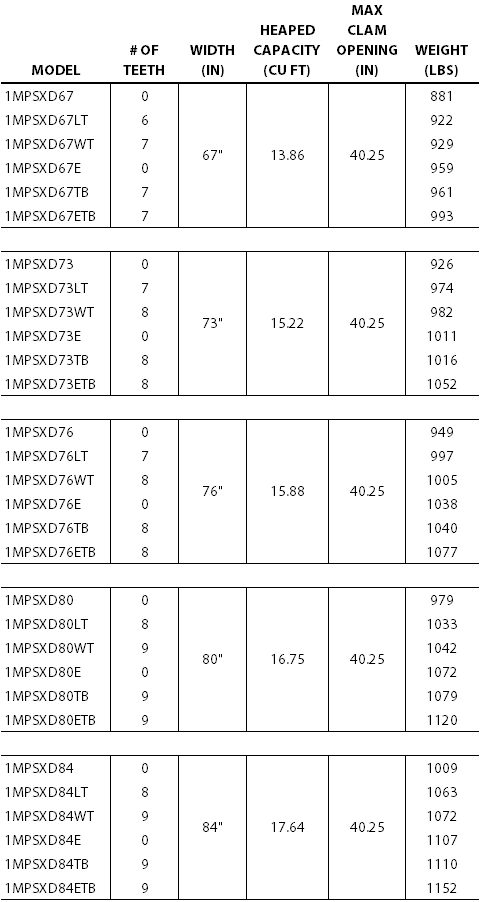

Severe Xtreme Duty Low Profile 4-IN-1 Multi-Purpose Bucket

4-In-1 Multi-Purpose Buckets, Rubber Tire Machines, Rubber Track Machines, Severe Xtreme, Skid Steer, General Purpose Buckets, Skid Steer, Tractor Loaders

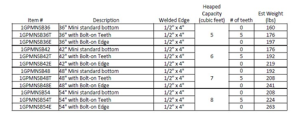

Severe Xtreme Duty Low Profile Bucket 4-IN-1 Multi-Purpose Attachment is designed for rubber tire and rubber track host machines up to 130 horsepower. This bucket is available in 67", 73", 76", 80" and 84" with the following options: bolt-on large teeth, weld-on teeth, bolt-on cutting edge, bolt-on tooth bar and extended tooth bar.

Product Features:

- For rubber tire or rubber track host machines up to 130 horsepower, and tractor loaders

- Low profile for improved load visibility

- Radius moldboard for improved material loading and unloading

- Pre-drilled 6” x ¾” front cutting edge to accommodate all bolt-on options

- Solid 6” x ¾” edge is attached to buckets with weld-on teeth

- Reversible bolt-on edge standard for dozer section

- Models include 67”, 73”, 76”, 80” and 84”

Front edge options:

- Bolt-on Large Teeth

- Weld-on Teeth

- Reversible Bolt-on Cutting Edge

- Bolt-on Tooth Bar

- Bolt-on Extended Tooth Bar

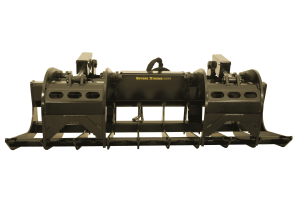

T-Rex Pallet Fork Grapple Attachment

PRODUCT FEATURES

The T-Rex Pallet Fork Grapple Attachment quickly mounts to any ISO-standard Class II ITA fork rail, transforming standard pallet forks into a powerful, multi-purpose grapple. Built from high-strength steel, the T-Rex is engineered for tough jobs and extreme durability. With an impressive 55-inch maximum opening and a 3,000 PSI hydraulic cylinder, the T-Rex delivers incredible clamping force, making it ideal for gripping, lifting, and hauling brush, logs, debris, and more with absolute control and power. Key Features:- Compatible with ISO Class II ITA fork rails

- Removable-Installs with a simple 3-bolt design-wrench included

- Converts pallet forks into a high-performance grapple

- Massive 55" max opening for large and irregular loads

- Powerful 3,000 PSI cylinder for exceptional clamp force.

- Heavy-duty construction from high-strength steel

TYRANT SERIES II

PRODUCT FEATURES:

- 1" thick blade carrier.

- 3/16" deck with 1/4" reinforcement

- Full Grappling & Grubbing ability with Thumb

- Recessed carrier design for bolt head protection

- Fully welded bolt protector on blade carrier

- 42" & 48" models have a two (2) blade cutting system

- 48cc GEAR-STYLE motor

- CASE DRAIN NOT REQUIRED

- Available jumper hose lengths: 6 ft, 8 ft, and 10 ft (Dealer Must Specify at Time of Order)

- Overall, Cutter Width: 42”

- Overall, Cutter Depth: 49”

- Overall, Cutter Height: 35”

- #of Blades: 2

- Blade Length: 11.94”

- Blade Width: 6”

- Cutting Capacity Diameter: 6”

- True Cut Width: 42”

- Min. Cut Height: 5/16”

- Oil Flow Required GPM: 10-32

- Tip Speed: 10K-14K

- Est. Weight LB 575

- Overall, Cutter Width: 48”

- Overall, Cutter Depth: 55”

- Overall, Cutter Height: 35”

- #of Blades: 2

- Blade Length: 11.94”

- Blade Width: 6”

- Cutting Capacity Diameter: 6”

- True Cut Width: 48”

- Min. Cut Height: 5/16”

- Oil Flow Required GPM: 10-32

- Tip Speed: 10K-14K

- Est. Weight LB 645

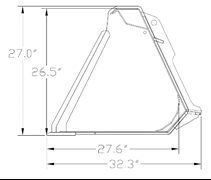

Ultra Duty 4-IN-1 Multi-Purpose Bucket

Ultra Duty 4-IN-1 Multi-Purpose Attachment is designed for rubber tire and rubber track host machines up to 130 horsepower. This bucket is available in 73", 76", 80" and 84" models. Side cutters come standard.

Product Features:

- For rubber tire or rubber track host machines loaders up to 130 horsepower

- For harsh environments such as: gravel, concrete, etc.

- 5/16” moldboard and additional reinforcement on dozer for added strength

- 1”x6” front weld in cutting edge

- Side cutters come standard

- AR plate reinforced flat bottom

XD Brush Cutter Series

Product Features:

- Triangular 5/8 Steel Vented Blade Carrier

- Cuts Trees up to 4” in Diameter

- Direct Drive EATON® Motor with Relief Valves

- One piece top deck design for strength and structural durability

- Standard Motor Cover & Spindle Guard

- Fully welded bolt protector on blade carrier

- Heavy duty round tube brush guard

- Motor does not require drain lines

- Available jumper hose lengths: 8 ft and 10 ft (Must Specify at Time of Order)

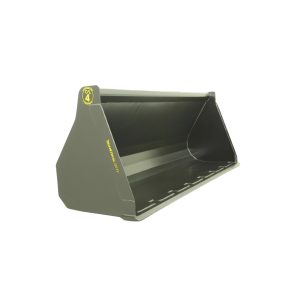

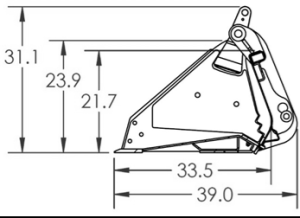

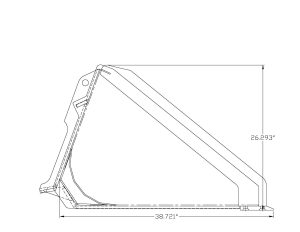

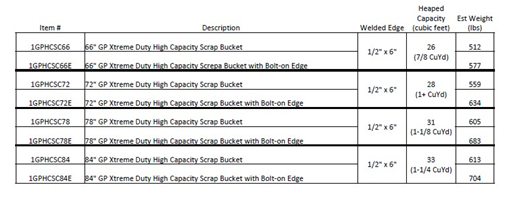

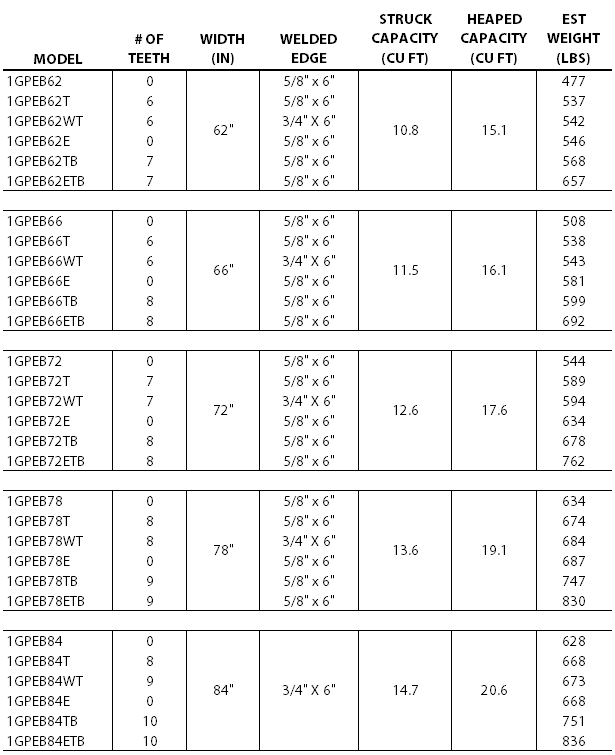

Xtreme Duty Extended Bottom Low Profile General Purpose Bucket

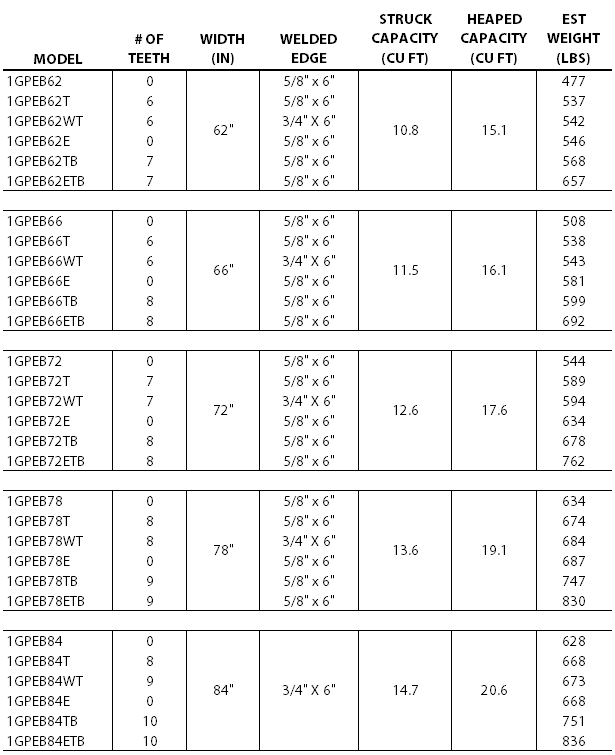

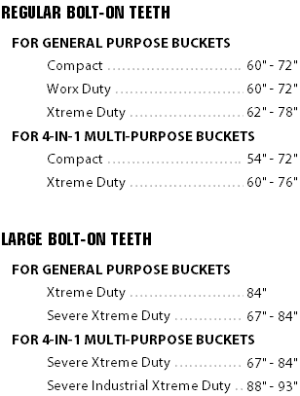

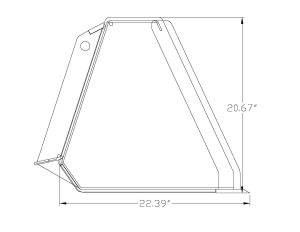

The XTREME Duty™ Extended Bottom Low Profile General Purpose Bucket Attachment is designed with a high-strength, abrasion-resistant front cutting edge pre-drilled to accommodate bolt-on attachment options, and is designed for compatibility with rubber tire host machines up to 100 horsepower or rubber track host machines up to 80 horsepower. This bucket attachment is available in 62", 66", 72", 78" and 84" models.

Product Features:

- For rubber tire host machines up to 100 horsepower or rubber track host machines up to 80 horsepower

- Extended bottom design provides front edge visibility for machine operator

- Radius moldboard for improved material loading and unloading

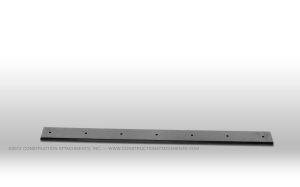

- Pre-drilled high-strength, abrasion-resistant front cutting edge accommodates all bolt-on attachments

- A solid edge is attached to buckets with weld-on teeth

- Models include 62”, 66”, 72”, 78”, and 84”

- Bucket sizes 62” – 78” have a 5/8” x 6" welded cutting edge

- 84” buckets have a ¾” x 6" welded cutting edge

- Bolt-on Teeth

- Weld-on Teeth

- Reversible Bolt-on Cutting Edge

- Bolt-on Tooth Bar

- Bolt-on Extended Tooth Bar